Aircraft Maintenance Management

Maintenance quality is a critical foundation for flight safety. It needs to perform aircraft inspections and maintenance tasks to ensure the reliability of aircraft systems. EVA Air adheres to the General Maintenance Manual (GMM) manufacturer technical specifications, and regulatory requirements in aircraft maintenance and operational monitoring. Each maintenance detail is diligently completed in accordance with these guidelines. Therefore, the cultivation of maintenance culture and disciplined implementation are the foundation of maintenance. Moreover, the spirit of “Safety First and Quality is everything” is also our primary criterion for aircraft maintenance.

In order to ensure the quality of maintenance, the Precision Measurement Equipment used in aircraft maintenance operations is based on the manufacture technical specifications of the equipment. Equipment is regularly sent for factory inspection and checked against national calibration standards such as the US National Institute of Standards and Technology (NIST) or equivalent to ensure compliance with the specifications of the manufacturer. Regardless of maintenance operations on the apron or in the hangar, relevant specific operation items require re-checking through the quality control inspection process or through flight verification to confirm the safety of the aircraft. These repeated inspections and rigorous maintenance operations reflect and ensure the standards of continuous airworthiness.

EVA Air truly grasps every detail of maintenance, from the safe service life of each component to the precise requirements of all maintenance procedures, in order to reduce all possible risks and implement flight safety. EVA Air not only insists on maintenance quality, but also sets dispatch rate target for each fleet. Dispatch rates and the reasons for aircraft delays are monitored and analyzed during monthly Quality Review Board. Aircraft maintenance plans are adjusted or engineering commands are executed to prevent delays and maintain the fleet dispatch target to provide safe and punctual flights.

Reliability Control Program

EVA Air collects and analyzes technical information and problems generated during daily operations in accordance with the Reliability Control Program to formulate maintenance methods for providing warning standards for aircraft abnormalities. In the event that aircraft abnormality rate exceeds the standard, engineers from different specializations are assigned to analyze and formulate improvement projects. The projects are incorporated into the aircraft maintenance plan in order to maintain the reliability of the aircraft system, improve maintenance quality and ensure flight safety.

The technical information and problem characteristics generated during the daily operation of the aircraft are divided by the Reliability Control Program into (1) System, (2) Components, (3) Powerplant, and (4) Structure for monitoring. The “Reliability Meeting” and the “Quality Review Board” convene regularly each month to monitor, discuss and formulate improvement for issues such as aircraft maintenance reliability, technical corrective and preventive measures, and human errors.

Safety Performance Indicator and Target

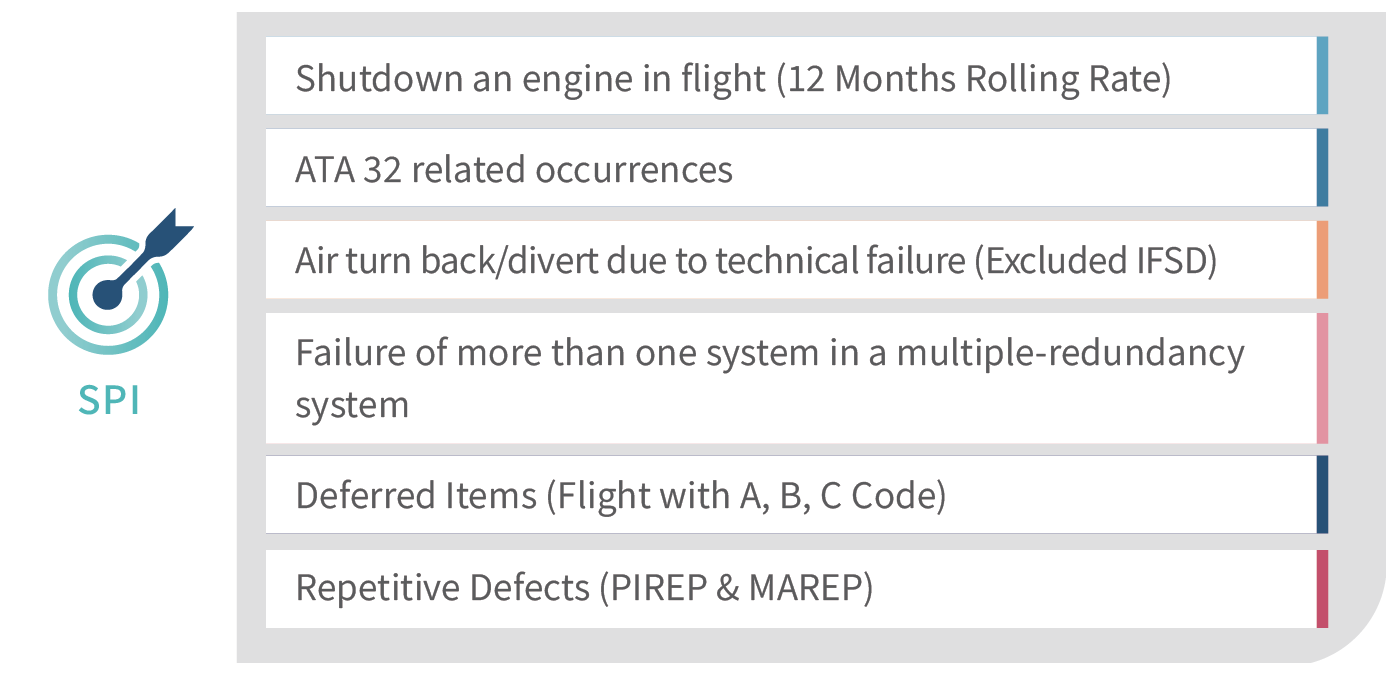

To effectively implement and measure the maintenance safety performance and ensure the implementation of the safety management system, the Engineering & Maintenance Div. has established corresponding Safety Performance Indicators (SPIs) and Safety Performance Targets (SPTs). The core elements of the safety management system, "Hazard Identification and Risk Management", are integrated into the thinking process and daily operations of employees. This enables the effective identification, assessment, and control of operating risks in maintenance activities, leading to improved safety performance and overall safety achievements.

Sustainable Innovation in Aircraft Maintenance

During aircraft sales and return, our employees proposed effective operational improvement plans to maximize the efficiency and life-cycle economic value of aircraft components. Furthermore, to improve the quality and efficiency of system services, we plan to integrate the existing e-check and i-fuel systems, incorporating both software and hardware components. The goal of this integration is to effectively improve user productivity and strengthen the Company’s overall competitiveness. In 2024, a total of 123 tablets incompatible with the Company’s system upgrade were donated to rural schools through the Chang Yung-Fa Foundation. This further advances our corporate sustainability development.

Operation Monitoring Management

Flight Control Department works around the clock for flight dispatch and control. The Flight Information System (FIS) and Flight Trace System provide access to flight-related status, and tracks changes in the external environment (e.g. airport and weather). For flight dispatch operation, the personnel responsible for drawing up flight plans are all qualified dispatchers with licenses issued by the CAA. With their expertise and assistance of the system, a safe, fuel-saving and comfortable journey is made possible on every EVA Air flight.

EVA Air participates in European Free Route Airspace Work Group, FAA Cross Polar Work Group (CPWG) and Informal Pacific ATC Coordinating Group (IPACG) to improve the European, North America, Russian Far East, North Pacific and Japan region Air Traffic Service (ATS) efficiency of transit flights. In addition, it discuss and develop a fuel-saving and time-saving route to reduce the impact of greenhouse gas and air pollutant emissions.